MOISTURE

CONTROL

Daily temperature fluctuations and weather cycles create humidity and condensation, causing moisture which can quickly degrade or damage stored products.

High ambient relative humidity often persists for long periods. Such conditions can create moist environments, leading to condensation that negatively impacts product quality. This can result in mould, mildew, or bacteria, causing spoilage.

At Cargotection, we offer various moisture reduction technologies for different applications. Our solutions include membrane and molecular sieve technologies, as well as automated aeration systems, all tailored to reduce humidity in storage areas or during product transport.

MEMBRANE

TECHNOLOGY

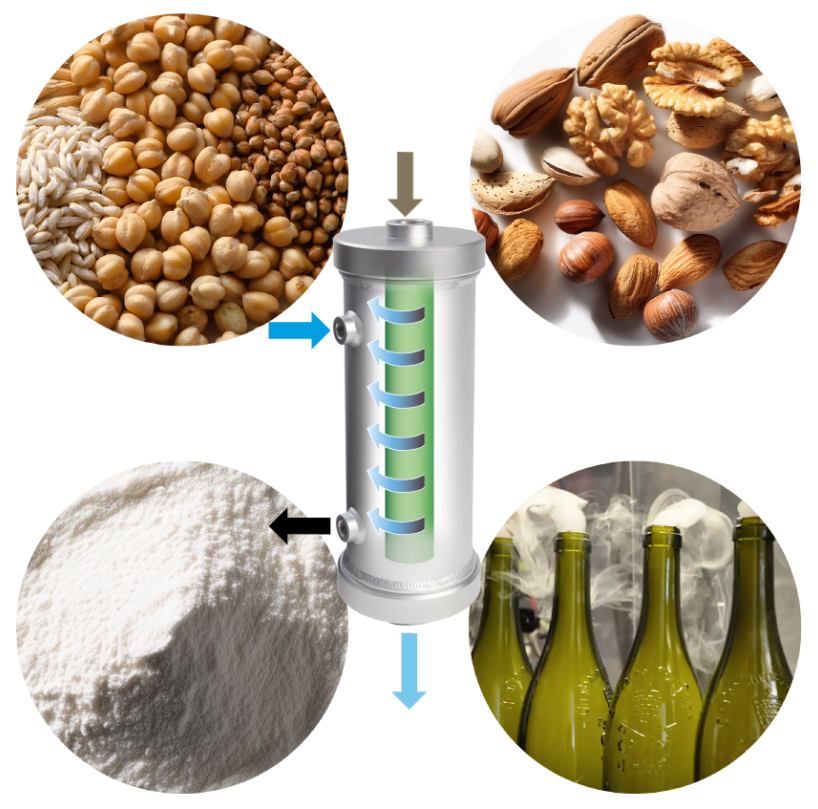

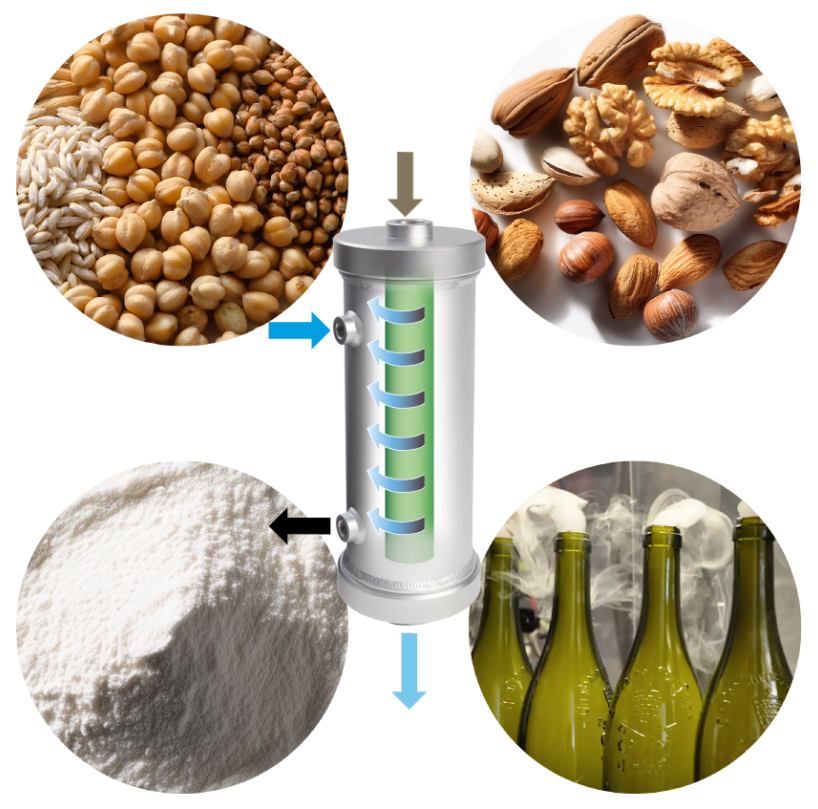

Our membrane technology separates moisture from ambient air and provides dry air for flushing out moisture from your storage area. It can create a protective dry blanket to protect your product.

Applications:

- Containers

- Silos

- Covered stockpiles

- Tarped bunkers

- Cabinet storage

- Portable cabinets

MOLECULAR SIEVE

TECHNOLOGY

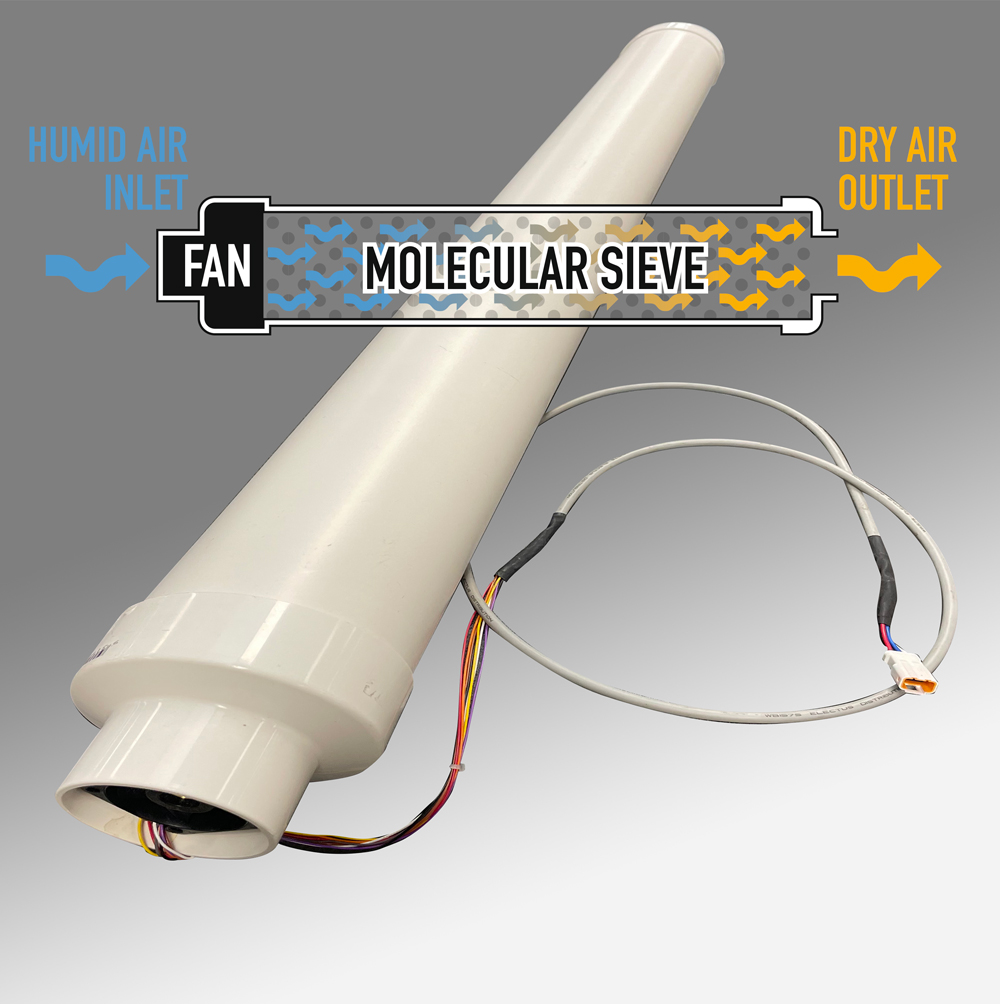

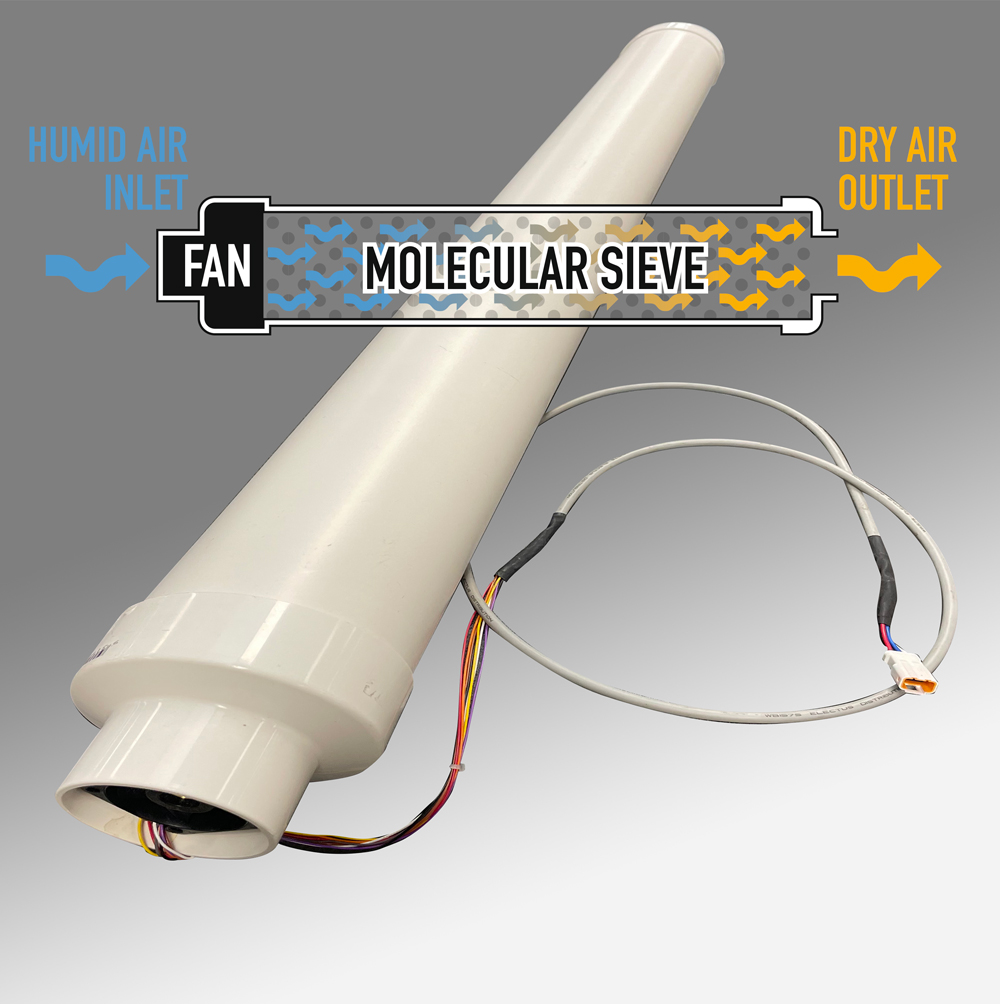

Low energy solution to reduce relative humidity levels in your storage area or transport container.

Water vapour is adsorbed into a molecular sieve and removed from the atmosphere of the enclosure.

Applications:

- Moisture control in shipping containers during sea voyage or on land

- Delivery truck transport

- Remote and rural moisture reduction

- Silo bags

AUTOMATIC AERATION

SYSTEMS

Automated Aeration systems are primarily used in stockpile moisture control.

Our Automated aeration systems incorporate a ‘smart’ system that detects humidity in the stockpile as well as in ambient Air and then runs Aeration Fans to bring humidity to a desired range.

Our systems are also suitable when Electrical Power is not available (such as on-farm) because our controllers have the ability to start and stop a genset automatically.

Applications:

- Covered stockpiles

- Tarped bunkers

- Silos

- Containers

Cargotection is equipped with the scope of knowledge, technical expertise and commercial application experience to provide the perfect solution to your produce requirements.

Cargotection Pty Ltd

368 Ferntree Gully Road

Notting Hill VIC Australia 3168

+61 3 9652 3600

info@cargotection.com